There are several techniques used in NDT for the collection of various types of data, each requiring its own kind of tools, training, and preparation.

Some of these techniques might allow for a complete volumetric inspection of an object, while others only allow for a surface inspection. In a similar way, some NDT methods will have varying degrees of success depending on the type of material they’re used on, and some techniques—such as Magnetic Particle NDT, for example—will only work on specific materials (i.e., those that can be magnetized).

Here are the eight most commonly used NDT techniques:

- Visual NDT (VT)

- Ultrasonic NDT (UT)

- Radiography NDT (RT)

- Eddy Current NDT (ET)

- Magnetic Particle NDT (MT)

- Acoustic Emission NDT (AE)

- Dye Penetrant NDT (PT)

- Leak Testing (LT)

1. VISUAL TESTING (VT)

Definition: Visual Non-Destructive Testing is the act of collecting visual data on the status of a material. Visual Testing is the most basic way to examine a material or object without altering it in any way.

How to Conduct Visual Testing

Visual Testing can be done with the naked eye, by inspectors visually reviewing a material or asset. For indoor Visual Testing, inspectors use flashlights to add depth to the object being examined. Visual Testing can also be done with an RVI (Remote Visual Inspection) tool, like an inspection camera. To get the camera in place, NDT inspectors may use a robot or drone, or may simply hang it from a rope.

2. ULTRASONIC TESTING (UT)

Definition: Ultrasonic Non-Destructive Testing is the process of transmitting high-frequency sound waves into a material in order to identify changes in the material’s properties.

How to Conduct Ultrasonic Testing

In general, Ultrasonic Testing uses sound waves to detect defects or imperfections on the surface of a material created.

One of the most common Ultrasonic Testing methods is the pulse echo. With this technique, inspectors introduce sounds into a material and measure the echos (or sound reflections) produced by imperfections on the surface of the material as they are returned to a receiver.

Here are some other types of Ultrasonic Testing:

- Phased Array Ultrasonic Testing (PAUT)

- Automated Ultrasonic Testing (AUT)

- Time-Of-Flight Diffraction (TOFD)

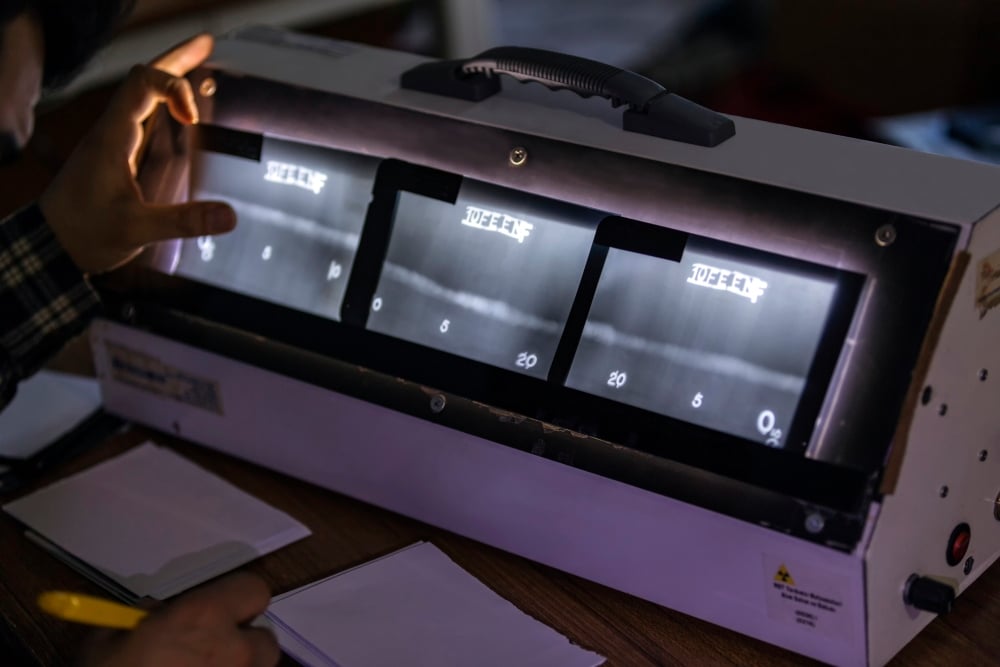

3. RADIOGRAPHY TESTING (RT)

Definition: Radiography Non-Destructive Testing is the act of using gamma- or X-radiation on materials to identify imperfections.

How to Conduct Radiography NDT Testing

Radiography Testing directs radiation from a radioactive isotope or an X-ray generator through the material being tested and onto a film or some other kind of detector. The readings from the detector create a shadowgraph, which reveals the underlying aspects of the inspected material.

Radiography Testing can uncover aspects of a material that can be hard to detect with the naked eye, such as alterations to its density.

4. EDDY CURRENT (ELECTROMAGNETIC) TESTING (ET)

Definition: Eddy Current Non-Destructive Testing is a type of electromagnetic testing that uses measurements of the strength of electrical currents (also called eddy currents) in a magnetic field surrounding a material in order to make determinations about the material, which may include the locations of defects.

How to Conduct Eddy Current Testing

To conduct Eddy Current Testing, inspectors examine the flow of eddy currents in the magnetic field surrounding a conductive material to identify interruptions caused by defects or imperfections in the material.

5. MAGNETIC PARTICLE INSPECTION (MPI)

Definition: Magnetic Particle Non-Destructive Testing is the act of identifying imperfections in a material by examining disruptions in the flow of the magnetic field within the material.

How to Conduct Magnetic Particle Inspection

To use Magnetic Particle Inspection, inspectors first induce a magnetic field in a material that is highly susceptible to magnetization. After inducing the magnetic field, the surface of the material is then covered with iron particles, which reveal disruptions in the flow of the magnetic field. These disruptions create visual indicators for the locations of imperfections within the material.

6. ACOUSTIC EMISSION TESTING (AE)

Definition: Acoustic Emission Non-Destructive Testing is the act of using acoustic emissions to identify possible defects and imperfections in a material.

How to Conduct Acoustic Emission Testing

Inspectors conducting Acoustic Emission Tests are examining materials for bursts of acoustic energy, also called acoustic emissions, which are caused by defects in the material. Intensity, location, and arrival time can be examined to reveal information about possible defects within the material.

7. DYE PENETRANT TESTING (PT)

Definition: Dye Penetrant Penetrant Non-Destructive Testing (also called Liquid Penetrant Testing) refers to the process of using a liquid to coat a material and then looking for breaks in the liquid to identify imperfections in the material.

How to Conduct Penetrant Testing

Inspectors conducting a Penetrant Test will first coat the material being tested with a solution that contains a visible or fluorescent dye. Inspectors then remove any extra solution from the material’s surface while leaving the solution in defects that “break” the material’s surface. After this, inspectors use a developer to draw the solution out of the defects, then use ultraviolet light to reveal imperfections (for fluorescent dyes). For regular dyes, the color shows in the contrast between the penetrant and the developer.

8. LEAK TESTING (LT)

Definition: Leak Non-Destructive Testing refers to the process of studying leaks in a vessel or structure in order to identify defects in it.

How to Conduct Leak Testing

Inspectors can detect leaks within a vessel using measurements taken with a pressure gauge, soap-bubble tests, or electronic listening devices, among others.